Top AI-powered Vehicle Inspection Alternative to Uveye: How Elscope Vision Advanced Vision Enhances Workshop Accuracy

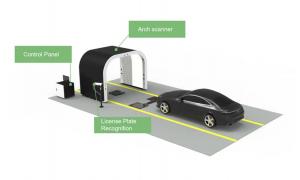

SHANGHAI, CHINA, January 28, 2026 /EINPresswire.com/ -- A luxury sedan pulls into a busy service center, the driver concerned about a faint rattling sound and a possible scratch from a tight parking garage. In the past, a service advisor would walk around the vehicle with a clipboard, squinting at body panels under flickering fluorescent lights and perhaps missing a small underbody scrape that could lead to future corrosion. Today, that same vehicle glides through a sleek, sensor-equipped archway. In seconds, high-resolution cameras and deep-learning algorithms have flagged a 2mm paint chip, measured tire tread depth with sub-millimeter precision, and generated a high-definition photo of the undercarriage. This is the reality of the Top AI-powered Vehicle Inspection Alternative to Uveye, a sector where New Tech Automotive Technology (Shanghai) Co., Ltd.,(NTA) known globally as Elscope Vision, is setting new benchmarks for transparency and speed.

The evolution of AI-powered vehicle inspection has moved rapidly from experimental research to an essential pillar of the modern automotive ecosystem. Historically, vehicle checks were manual and subjective, prone to human error and inconsistent reporting. The first wave of innovation introduced digital cameras, but it was the integration of sophisticated computer vision and neural networks that truly revolutionized the field. Current trends show a decisive shift toward "drive-through" systems that combine multi-angle hardware with cloud-based diagnostics, allowing workshops to process high volumes of vehicles with 100% consistency. As dealerships and repair hubs face mounting pressure to increase throughput while maintaining customer trust, the move toward automated vehicle inspection has become an industry standard rather than a luxury.

The Elscope Vision Legacy: From Shanghai to a Global Standard

Founded in 2014 and headquartered in Shanghai, New Tech Automotive Technology (NTA) emerged with a clear mission: to solve the "trust gap" in automotive services through technology. Recognized as a national high-tech enterprise, Elscope Vision has spent over a decade mastering full-stack R&D. This includes everything from the precision engineering of hardware and automation to the development of proprietary AI algorithms and cloud architecture. Under the brand name Elscope Vision, the company has transformed from a domestic pioneer into a global leader, with solutions now deployed in more than 40 countries across Europe, the Americas, Asia, and Australia.

The brand's core philosophy centers on four pillars: Innovation, Quality, Expertise, and Sustainability. By leveraging the latest in AI, Elscope Vision continuously pushes the boundaries of automotive diagnostics. Their commitment to quality ensures that every scan meets the highest global standards for reliability, while their deep expertise in China’s competitive automotive landscape provides a foundation for global excellence. Beyond technical metrics, Elscope Vision is dedicated to the construction of green cities and the creation of a better future by promoting efficient, paperless, and accurate maintenance cycles that extend vehicle lifespans and reduce waste.

Precision Engineering: The Elscope Vision Technology Suite

Elscope Vision provides a comprehensive suite of advanced inspection equipment designed to cover every inch of a vehicle. Their AI-powered vehicle inspection systems utilize arrays of industrial-grade cameras to conduct seamless 360-degree scans. Whether it is the AI Vehicle Exterior Inspection system or specialized Underbody and Tire scanners, the technology is built to detect what the human eye often misses.

The technical core of these systems lies in their deep-learning analysis. Trained on millions of defect samples, the AI damage detection systems can identify and quantify scratches, dents, and even missing components as small as 0.5mm. This level of detail is particularly crucial for the used car market. For example, a large-scale used car auction platform recently implemented Elscope Vision’s 360-degree scanners to standardize their condition reports. Before this integration, disputes over undisclosed damage were a frequent bottleneck. After deployment, the platform reported a 40% reduction in inspection time and a significant surge in buyer confidence, as every vehicle was accompanied by an objective, traceable digital twin.

In another instance, a high-volume logistics hub utilized the Underbody Inspection system to monitor fleet health. By identifying early signs of anti-corrosion layer damage and structural wear, the hub shifted from reactive repairs to predictive maintenance, effectively lowering long-term operational costs and preventing roadside breakdowns. These success stories highlight how digital inspection technology serves as a bridge between technical data and business profitability.

The Strategic Alternative to Uveye: Enhancing Workshop Accuracy

While the industry often looks to UVeye as a pioneer, Elscope Vision has emerged as the Top AI-powered Vehicle Inspection Alternative to Uveye by offering a versatile, high-precision, and cost-effective ecosystem tailored for diverse global markets. NTA-Elscope Vision enhances workshop accuracy through several key differentiators:

Full-Stack Vertical Integration: Unlike many competitors that rely on third-party hardware or software, Elscope Vision maintains complete control over the entire production chain. This ensures that the hardware and AI algorithms are perfectly synchronized, leading to higher processing speeds and fewer system errors in high-demand environments.

Millimeter-Level Detection: Elscope Vision systems are engineered for "pixel-level precision." While standard vehicle inspection by Uveye offers robust scanning, Elscope Vision’s systems excel in identifying minute paint imperfections and hidden underbody risks, such as structural corrosion or loose fasteners, in cluttered or low-light environments.

Adaptable Global Deployment: Having scaled across 40+ countries, Elscope Vision has optimized its advanced inspection equipment to handle a wide range of vehicle types—from compact EVs to heavy commercial buses—and various environmental conditions, from the humid climates of Southeast Asia to the cold winters of Northern Europe.

Seamless Workshop Workflow: Elscope Vision focuses heavily on the "User Experience" for service advisors. The automated vehicle inspection results are integrated into intuitive, cloud-based reports that can be shared instantly with customers via mobile devices. This transparency allows workshops to show, rather than just tell, why a specific repair is necessary, leading to higher approval rates for service recommendations.

As the automotive world moves toward software-defined vehicles and autonomous fleets, the requirement for objective, data-driven health checks will only grow. New Tech Automotive Technology (Shanghai) Co., Ltd. stands at the forefront of this transition. By combining the agility of a high-tech innovator with the reliability of an established global provider, Elscope Vision is not just an alternative; it is the new standard for precision in the automotive service industry.

For more information on NTA’s intelligent vehicle inspection solutions, visit: https://www.elscopevision.com/.

The evolution of AI-powered vehicle inspection has moved rapidly from experimental research to an essential pillar of the modern automotive ecosystem. Historically, vehicle checks were manual and subjective, prone to human error and inconsistent reporting. The first wave of innovation introduced digital cameras, but it was the integration of sophisticated computer vision and neural networks that truly revolutionized the field. Current trends show a decisive shift toward "drive-through" systems that combine multi-angle hardware with cloud-based diagnostics, allowing workshops to process high volumes of vehicles with 100% consistency. As dealerships and repair hubs face mounting pressure to increase throughput while maintaining customer trust, the move toward automated vehicle inspection has become an industry standard rather than a luxury.

The Elscope Vision Legacy: From Shanghai to a Global Standard

Founded in 2014 and headquartered in Shanghai, New Tech Automotive Technology (NTA) emerged with a clear mission: to solve the "trust gap" in automotive services through technology. Recognized as a national high-tech enterprise, Elscope Vision has spent over a decade mastering full-stack R&D. This includes everything from the precision engineering of hardware and automation to the development of proprietary AI algorithms and cloud architecture. Under the brand name Elscope Vision, the company has transformed from a domestic pioneer into a global leader, with solutions now deployed in more than 40 countries across Europe, the Americas, Asia, and Australia.

The brand's core philosophy centers on four pillars: Innovation, Quality, Expertise, and Sustainability. By leveraging the latest in AI, Elscope Vision continuously pushes the boundaries of automotive diagnostics. Their commitment to quality ensures that every scan meets the highest global standards for reliability, while their deep expertise in China’s competitive automotive landscape provides a foundation for global excellence. Beyond technical metrics, Elscope Vision is dedicated to the construction of green cities and the creation of a better future by promoting efficient, paperless, and accurate maintenance cycles that extend vehicle lifespans and reduce waste.

Precision Engineering: The Elscope Vision Technology Suite

Elscope Vision provides a comprehensive suite of advanced inspection equipment designed to cover every inch of a vehicle. Their AI-powered vehicle inspection systems utilize arrays of industrial-grade cameras to conduct seamless 360-degree scans. Whether it is the AI Vehicle Exterior Inspection system or specialized Underbody and Tire scanners, the technology is built to detect what the human eye often misses.

The technical core of these systems lies in their deep-learning analysis. Trained on millions of defect samples, the AI damage detection systems can identify and quantify scratches, dents, and even missing components as small as 0.5mm. This level of detail is particularly crucial for the used car market. For example, a large-scale used car auction platform recently implemented Elscope Vision’s 360-degree scanners to standardize their condition reports. Before this integration, disputes over undisclosed damage were a frequent bottleneck. After deployment, the platform reported a 40% reduction in inspection time and a significant surge in buyer confidence, as every vehicle was accompanied by an objective, traceable digital twin.

In another instance, a high-volume logistics hub utilized the Underbody Inspection system to monitor fleet health. By identifying early signs of anti-corrosion layer damage and structural wear, the hub shifted from reactive repairs to predictive maintenance, effectively lowering long-term operational costs and preventing roadside breakdowns. These success stories highlight how digital inspection technology serves as a bridge between technical data and business profitability.

The Strategic Alternative to Uveye: Enhancing Workshop Accuracy

While the industry often looks to UVeye as a pioneer, Elscope Vision has emerged as the Top AI-powered Vehicle Inspection Alternative to Uveye by offering a versatile, high-precision, and cost-effective ecosystem tailored for diverse global markets. NTA-Elscope Vision enhances workshop accuracy through several key differentiators:

Full-Stack Vertical Integration: Unlike many competitors that rely on third-party hardware or software, Elscope Vision maintains complete control over the entire production chain. This ensures that the hardware and AI algorithms are perfectly synchronized, leading to higher processing speeds and fewer system errors in high-demand environments.

Millimeter-Level Detection: Elscope Vision systems are engineered for "pixel-level precision." While standard vehicle inspection by Uveye offers robust scanning, Elscope Vision’s systems excel in identifying minute paint imperfections and hidden underbody risks, such as structural corrosion or loose fasteners, in cluttered or low-light environments.

Adaptable Global Deployment: Having scaled across 40+ countries, Elscope Vision has optimized its advanced inspection equipment to handle a wide range of vehicle types—from compact EVs to heavy commercial buses—and various environmental conditions, from the humid climates of Southeast Asia to the cold winters of Northern Europe.

Seamless Workshop Workflow: Elscope Vision focuses heavily on the "User Experience" for service advisors. The automated vehicle inspection results are integrated into intuitive, cloud-based reports that can be shared instantly with customers via mobile devices. This transparency allows workshops to show, rather than just tell, why a specific repair is necessary, leading to higher approval rates for service recommendations.

As the automotive world moves toward software-defined vehicles and autonomous fleets, the requirement for objective, data-driven health checks will only grow. New Tech Automotive Technology (Shanghai) Co., Ltd. stands at the forefront of this transition. By combining the agility of a high-tech innovator with the reliability of an established global provider, Elscope Vision is not just an alternative; it is the new standard for precision in the automotive service industry.

For more information on NTA’s intelligent vehicle inspection solutions, visit: https://www.elscopevision.com/.

New Tech Automotive Technology(Shanghai) Co., Ltd.

New Tech Automotive Technology(Shanghai) Co., Ltd.

+86 17717670602

mktdept@ntatchina.com

Visit us on social media:

LinkedIn

Facebook

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.